No need to mold internal threads by tapping / Enables significant cost reduction

When using machine screw, normal method is to form internal thread by tapping after drilling or punching pilot hole.

However, internal thread is not required to be tapped by using DELTITE screws.

DELTITE screw itself acts as a tap / it is screwed and clamped while forming an internal screw.

Therefore, DELTITE screws enable significant cost reduction as no tap cost is required.

Low driving torque / Excellent work efficiency

Compared to various tapping screws, DELTITE screw has a spoon-shaped tip that gradually forms an internal thread.

Therefore, its screwing torque is extremely low, which helps to improve work efficiency and reduce operator fatigue.

Strong holding power / Rarely loose by vibration or shock

Needless to say, holding power of DELTITE screws is higher than that of machine screws.

Various tapping screws easily get loose due to reduction of contact area with internal thread. It is because large diameter pilot hole is made to facilitate clamping work.

In addition, the internal thread may get damaged.

Since DELTITE screw itself form internal thread plastically, DELTITE screw and the internal thread are in perfect contact with each other, which is very effective in

preventing looseness.

Little swarf

Self drilling tapping screw may not be usable depending on the product because swarf is generated when it is screwed.

DELTITE screw itself form internal thread plastically on opponent material and swarf should be decreased.

DELTITE-3 is designed to be compatible to machine screw.

Outer diameter of DELTITE-3 is slightly larger than that of the machine screw.

Machine screw can be used for replacement in case of lost.

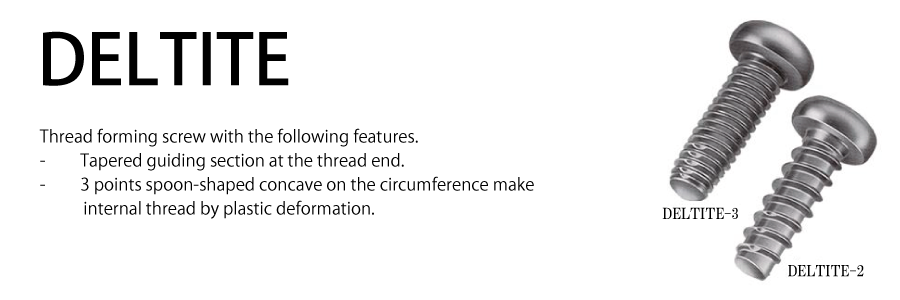

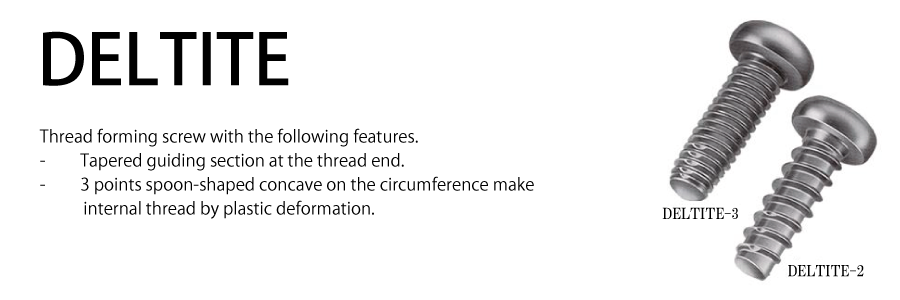

Structure of DELTITE screw

DELTITE screw has tapered guiding section at the thread end and 3 points spoon-shaped concave over several threads on the circumference make internal thread by plastic deformation.

DELTITE screw is differentiated to DELTITE-2 and DELTITE-3 by the threaded part shape.

The threaded part of DELTITE-2 has the same outer diameter and pitch as tapping screw type 2.

Outer diameter of DELTITE-3 is slightly larger than that of machine screw JIS* class 2 and their pitches are same.

In addition, its material is low-carbon steel with carburization quenching and tempering,

whose characteristics of tapping screw is fully utilized.

*Japanese Industrial Standards

>>Back to the previous page